A. Application and Principle

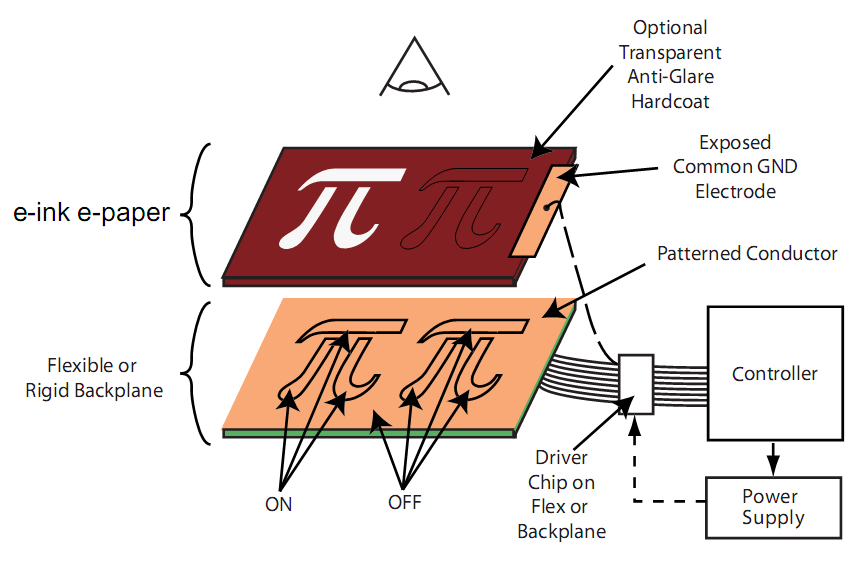

Custom segmented e-paper display products are available from Good Display. Segmented e-paper displays are used for many applications including electronic shelf labels, electronic scale, electronic signs, clocks, and smart cards. The e-paper is laminated on a flexible or rigid electrode-patterned substrate, individually addressing each segment. This enables the substrate and individual segment to be directly driven and separately controlled.

E-Paper is made up of millions of tiny microcapsules, about the diameter of a human hair. Each microcapsule contains positively charged white particles and negatively charged black particles suspended in a clear fluid. When a positive or negative electric field is applied, corresponding particles move to the top of the microcapsule where they become visible to the viewer.

E-paper takes designs to a new level. Unlike LCDs which are made with glass, our material is extremely thin and flexible. Readable like paper, it is visible in sunlight with nearly a 180 degree viewing angle. Ideal for your power budget, e-ink e-paper prolongs battery life, drawing power only when switching due to its bistable image characteristics. Custom shapes enlarge your possibilities.

The tooling cost for matrix E-paper is very expensive,about $1 million, and few people can afford to it, so here we just talk about how to custom Segmented E-Paper display.

Applications for the technology are broad, including a wide variety of consumer electronics, watches, medical devices, industrial gauges, PC accessories, smart cards,electronic shelf labels, and mobile communications.

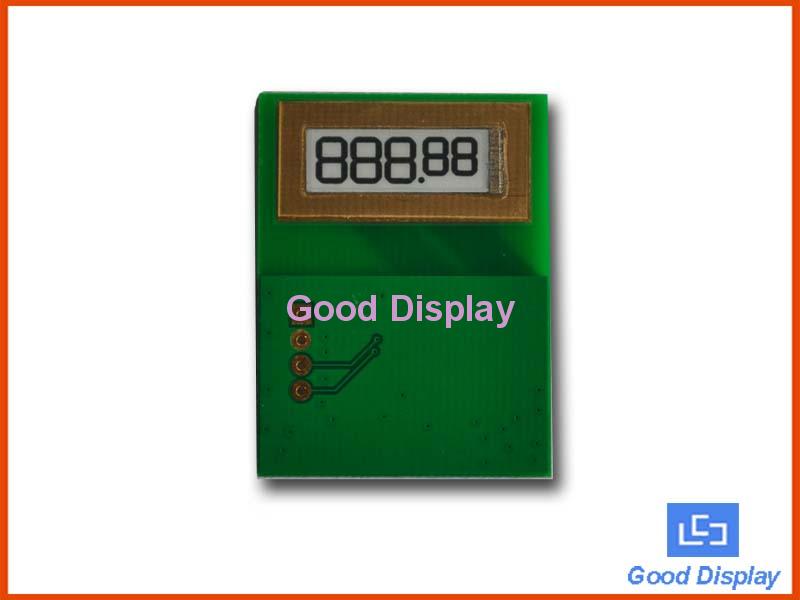

And we offers two types of Segmented displays: Segmented Display Cells (SDCs), and Segmented Display Modules (SDMs).

SDCs are independent display cells that do not include any embedded electronics; they can be driven at either 5V or 15V. Typically, SDCs are used in simpler designs with lower segment counts and fewer pin outs. Designs that have adequate space and less restrictive PCB integration needs are ideal for SDC applications.

SDMs include an integrated E Ink display driver for a complete display solution, typically for designs that have demanding integration requirements. SDMs simplify the integration effort by reducing the number of pin outs required between the MCU and display. As a result, less space is needed for connection to the PCB.

B. Backplane Type

Usually, there are 3 kinds material as the backplane of segmented e-paper display.

1. FPC Backplane

|

Segmented SDM front side (COF Packaging)

|

Segmented SDM back side

|

|

Segmented SDC front side

|

Segmented SDC back side

|

2. PCB Backplane

|

Segmented SDM front side

|

Segmented SDM back side (COB Packaging)

|

3. Glass Backplane

|

Black white two pigment color SDM Black white two pigment color SDM

(COG packaging)

|

Black white Red three pigment color SDM

(COG packaging)

|

C. Display mode

1. Two Colors Display

|

Black-White mode |

Green-White mode |

Red-White mode |

Blue-Whie mode |

2. Three Colors Display

Black,White,Red Tri-color mode, Black, White, Yellow Tri-color mode

D. Benefits

The disruptive benefits of E Ink Segmented displays include:

-

Ultra Low Power:E-paper displays are bi-stable, drawing power only when updating the display. Consuming approximately 0.5 micro amps per cm2 while switching the display, E Ink displays require zero power to display a static image.

-

Thinness: Segmented e-paper display thickness can be between 380 and 560 microns.

-

Rugged:Segmented e-paper displays are non-glass and shatterproof for added durability.

-

High contrast:Segmented e-paper displays are daylight readable with a 180 degree viewing angle.

-

Design:Segmented e-paper displays can be manufactured in any 2D shape such a circle, triangle, or abstract shape, enhancing industrial designs. In addition, E Ink's unique capabilities allow for the foreground and background to be reversed from black on white or white on black.

The related documents: